Case Study – Testronic Labs’ Film & Video Master File QC Lab

Project: Build facility to QC film and video master files (1TB+)

Background

As the Entertainment Industry was transitioning from digital tape to file-based workflows, one of the biggest challenges was file size. Master content files, at the highest level of resolution, are enormous, often easily exceeding 1TB. Not only was this an issue for storage, but also playback. There was only one tool that could play files of that size in real time and it was extremely expensive.

Testronic Labs offered content QA/QC services originally for video tape, then DVD and Blu-ray, for major Hollywood Studios. It was critical to adapt to a file-based workflow.

Project

Testronic was entirely geared to disc-based QC, with a representative matrix of DVD and Blu-ray players meticulously assembled to ensure comprehensive testing. The goal was to ensure that regardless of the player consumers owned, they had an excellent and identical viewing experience.

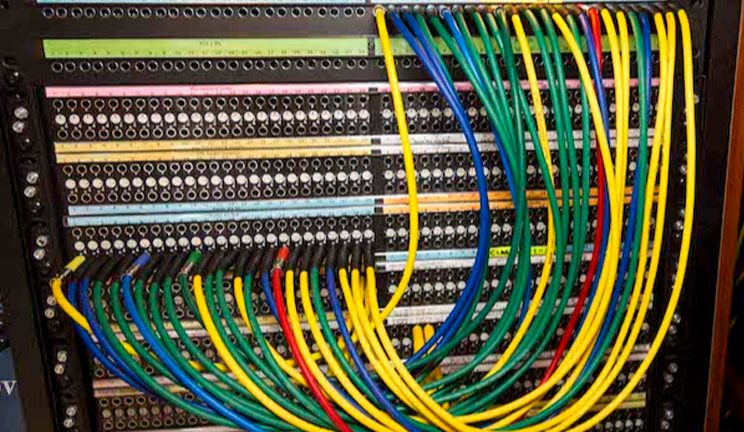

In order to start providing QA/QC services for files, we had to build the infrastructure from the ground up, literally. Requirements included:

- Security – MPAA audited physical and digital security

- Infrastructure

- Dedicated HVAC due to the heat generated by the equipment

- A raised floor to run cabling

- High bandwidth data lines using dark fiber (i.e., not connected to the internet)

- Automation – Automated ingest of both files to be QC’d and metadata

- File Management – Custom file and project tracking software

Following project management best practices, some steps we took included:

- Initiate – I drafted the project charter and got signoff from the stakeholders

- Plan – I drafted the scope and budget documents, got approval from the stakeholders and developed the project, communication, and risk management plans.

- Execute

- We dedicated a large space in our facility, installed a raised floor so we could run cables, and built a specially cooled room-within-a-room to protect the equipment. I hired teams for construction, high-capacity wiring, and equipment installation. Fortunately, we had the best testers in the business, so I didn’t need to hire an external team for that purpose. I worked with a vendor to customize a new piece of gear to playback large files at a fraction of the cost of the existing tool in the market. The team installed and iteratively tested all the equipment until it was working flawlessly.

- I oversaw the first file QC.

- Monitor

- I met with the teams and tracked progress daily.

- I submitted weekly reports to the stakeholders.

- Close – The build-out went very smoothly, so there were no significant loose ends to wrap up in closing other than submitting the final progress report and budget reconciliation.

Postscript

We won the Creativity and Innovation Award from the Hollywood Professional Alliance for our lab.